Introduction

Maintaining a well-organized maintenance program for your semi-truck is a key component of running a successful truck driving business. Since your ability to generate income is heavily dependent on the smooth operation of your vehicle, being stranded on the side of the road will not help your situation. The following comprehensive guide contains invaluable insights from seasoned owner-operators and reputable trucking companies to assist you in effectively maintaining your truck and ensuring uninterrupted journeys. So, let’s dive in and discover the key practices that will keep your wheels rolling and your business thriving.

What is Preventative Maintenance?

Preventative Maintenance is a vital practice that enables truckers to identify and address issues regarding their chariot in time, to prevent breakdowns and road-side problems. By proactively attending to your truck’s maintenance demands, you can save significant time and money in the long run.

So, let’s look at some features truckers need to ensure that their truck is performing optimally and providing benefit to their businesses.

- Conducting methodical assessments (including your pre-trip and post-trip inspections) is crucial in ensuring the reliability of your truck. By consistently carrying out thorough assessments before and after each journey, you establish a proactive approach that safeguards against potential issues and enhances overall safety.

- Addressing any discovered defects promptly, regardless of their seemingly minor nature, is essential. Don’t underestimate the importance of swift repairs as soon as issues are identified. By taking immediate action, you prevent small defects from escalating into more significant problems that can disrupt operations and lead to costly repairs.

- Allocate resources towards implementing a structured maintenance program to ensure the mechanical integrity and safe operational condition of your truck. By investing in a scheduled maintenance regimen, you proactively preserve the reliability and safety of your vehicle. This strategic approach not only minimizes the risk of unexpected breakdowns but also promotes optimal performance and extends the lifespan of your truck.

Each truck producing company sets a precedent and provides maintenance information to truck owners to sign-up with a maintenance provider and consult qualified professional maintenance service providers for repairs, optimal time for inspections and preventative advice for routine check-ups and so on.

What’s the maintenance cost for taking care of your vehicle?

Well, if maintenance was that easy, there would be “one-size-fits-all ” for all maintenance checks, but that is not the case. Moreover, it is even harder to specify the exact amount of funds required regarding maintenance costs for vehicles.

On average a cost of around $ 15000 per year is a reasonable estimate to begin with, but this

amount increases as the vehicle ages and gets older.

Effectively managing semi-truck maintenance costs can be achieved through a proactive approach, making it one of the most manageable expenses. By allocating resources towards regular maintenance, one can extend the lifespan of the truck and significantly reduce the likelihood of incurring substantial repair costs.

Managing semi-truck maintenance costs becomes effortless when adopting a proactive mindset. By proactively investing in routine maintenance, you can not only extend your truck’s lifespan but also minimize the occurrence of significant repair expenses.

In order to enhance cost optimization strategies, it is advantageous to conduct a thorough comparison of routine maintenance costs offered by well-established dealerships as well as reputable truck repair chains like Love’s, TA, and Ryder.

Some of the most common problems which truck drivers need to be on top of are:

- Hoses

- Alternators

- Wiring

- Brakes

- Airlines

Truckers need to be ever vigilant of these specific parts which can reduce the overall cost of maintenance, if the issues with these parts are identified and mitigated, they can reduce the overall maintenance cost quite significantly.

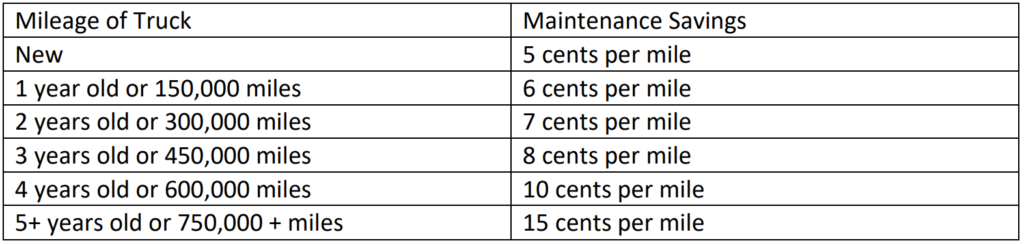

It might be considered a valuable approach and mindset to plan a maintenance budget per mile.

Please note that the table below is an estimate, for exact figures always consult your maintenance provider.

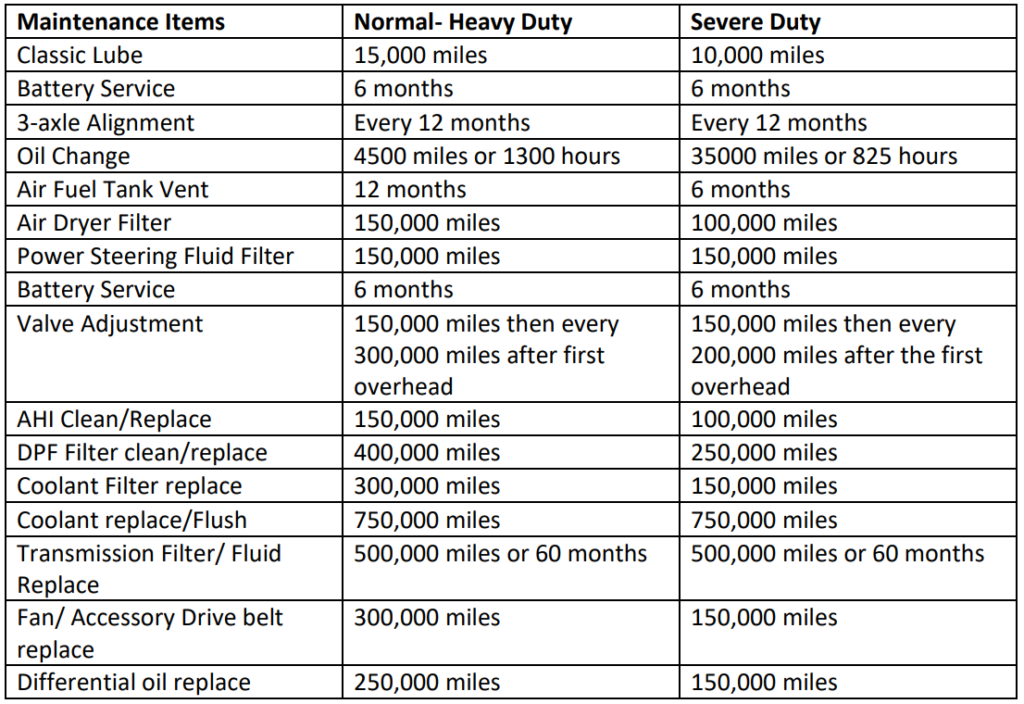

Some common maintenance intervals are listed below, again be sure to consult your manufacturer, as the values provided in the table below vary across the different makes and models of trucking vehicles.

A change for all seasons

A truck driver, must always be prepared to account the weather into maintenance inspections and prevention for their vehicle. For example, truck driving in the winters will affect the wear and tear of the vehicle differently than summers

Hot temperatures

- Air conditioning must be checked, especially the air filter for leakage and too much accumulation of debris.

- The coolant must be drained, flushed and pressurized at least once in a year.

- Check the battery for acid spillage, corrosion, ensure that the battery harness is secured well and tight

- Provide adequate air pressure, keeping in mind the tire expansion due to heat, to avoid tire bursts.

Cold Temperatures

- Check the windshield, for hail or rain aftermath, ensure that the wipers are clean and the rubber on them is not rotting.

- Double check on the brakes and make sure that the ABS system is working properly before initiating a winter drive, brakes can freeze in frigid temperatures, always make sure to inspect them by moving the truck.

- Check the engine fluids regularly.

- Check air pressure in the tires following federal regulations compliance.

- Get the truck washed regularly since, road salt is highly corrosive and cause damage to vehicle and the tires.

Conclusion

If truck drivers can identify, mitigate and follow the guidelines to adhere to a strict maintenance regimen, they can ensure more time on the road, without the hiccups and breakdowns and ensure productivity and value to their businesses.